Hinges make the door, for without quality hinges, the world's greatest door is a creaking menace to traffic. So, correctly selecting hinges is a crucial job for any construction project that involves doors: Hinges make the door, for without quality hinges, the world's greatest door is a creaking menace to traffic. So, correctly selecting hinges is a crucial job for any construction project that involves doors:

. Dependable, quality hinges, last for many years, giving smooth, quiet service.

. Dependable, quality hinges fit their templates (where templates are used) neatly, and are strong enough to take extra stresses when required.

. Dependable, quality hinges install easily.

. Dependable, quality hinges seldom call attention to themselves, unless

for excellence of fit and finish.

The simplest way to select good hinges is to check and see if hinges meet requisite ANSI or UL standards, where those standards are applicable. Too, be smart, and buy from a maker you can trust, one with almost 100 years in the door hardware business: S. Parker.

Selecting Proper Hinges

To select the proper hinge the following factors should be considered:

. The material of the door and frame determine method of application, i.e. mortised, surface mounted, half surface mounted, or half mortised.

. The size, thickness and weight of the door—wider doors, put more strain on hinges, so taller hinges should be used. Thicker doors require wider hinges. Heavy doors require taller, heavier gauge, narrower hinges.

. Clearance of the trim when a door swings 180° affects the width of the hinge.

. The frequency of use and the abuse the door will be subjected to affect hinge choice.heavy duty ball bearings, standard ball bearings or non-ball bearing hinges. It also affects the need for additional hardware such as closers, panic devices, etc.

Size of Door

The size of the door, and its weight, are critical in selecting a hinge that meets durability needs without exceeding cost allowances. The size and weight of the door, and its related accessory hardware, also help determine the number of hinges the door will require.

Exposure of Hinges

. Under normal exposure conditions, use either brass finished or Bonderized or Duranodic hinges.

. Plated steel hinges, in polished brass, antique brass and similar finishes, go with architectural details where the plated finish is needed.

. Solid brass hinges are superb for exteriors because they do not rust.

. Stainless steel hinges are great for corrosive atmospheres, especially for seashore use.

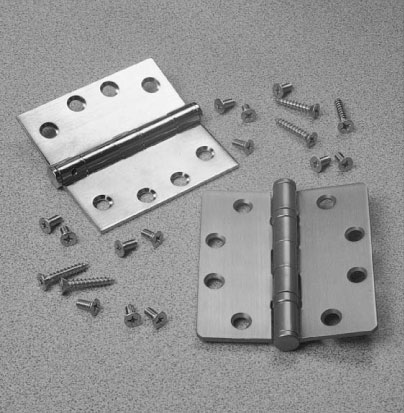

Hinges Materials

. Steel hinges may be Bonderized coasted for painting, with a prime coat coming before the Bonderized coat. Normal uses.

. Steel hinges may be plated in polished brass, antique brass or similar finishes, for use where the plated finish suits the application.

. Solid brass hinges are polished and finished, and the pins are stainless steel.

. Stainless steel hinges contain stainless steel pins and tips also. |